Essig Research is a leading provider of high-tech engineering and manufacturing services.

We leverage our engineering and technical expertise to develop value-driven solutions.

Our customer partnerships foster innovation and enable us to deliver superior results.

Essig Research is a leading provider of high-tech engineering and manufacturing services.

We leverage our engineering and technical expertise to develop value-driven solutions.

Our customer partnerships foster innovation and enable us to deliver superior results.

Essig Research is ISO 9001 certified and committed to providing quality services.

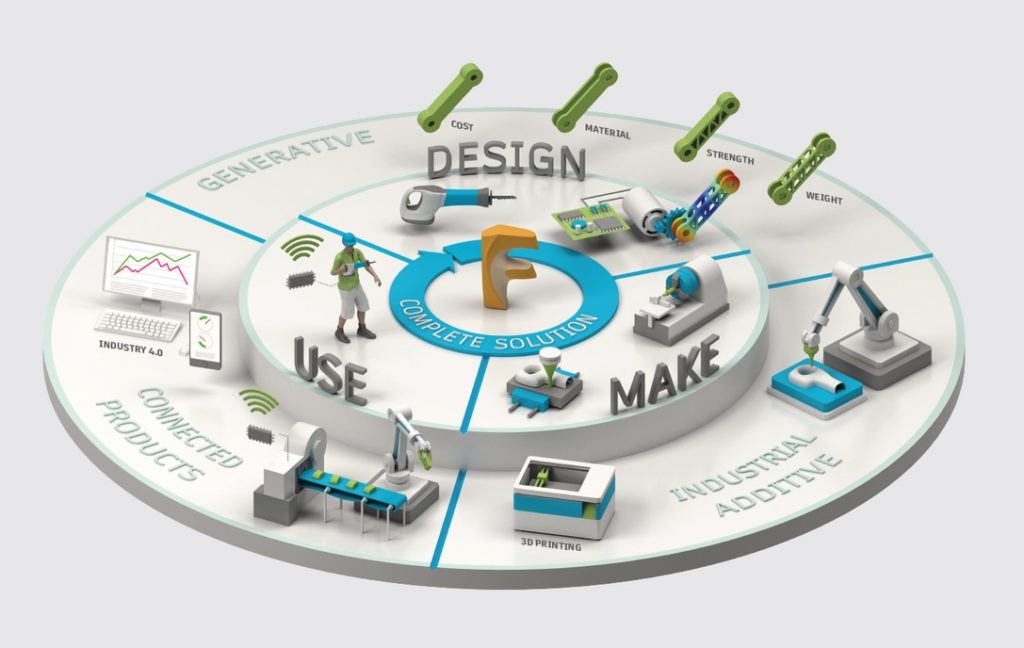

Product Lifecycle

Management

(PDM/PLM)

- ProductCenter PLM

- PDM/PLM Administration

- Configuration Management

- Methods Development

Research &

Development

(R&D)

- Material Testing

- Process Development

Preliminary

Design / Analysis

(PDA)

- CFD Analysis

- Heat Transfer

- Stress

- Frequency

- Lifing

Product Definition

Engineering

(PDE)

- Parametric Modeling

- Solid Model Design

- Detailing

- Model Based Definition

- Major Platforms Supported

Test Facility

Engineering

(TFE)

- Facility Layout & Design

- Test Rig Development

- Data Acquisition

New Product

Introduction

(NPI)

- Casting Drawings

- Machining Drawings

- Assembly Drawings

- Tool & Fixture Design

- Manufacturing Engineering

- Program Management

Maintenance, Repair

& Overhaul

(MRO)

- Repair Development

- Tool & Fixture Design

- Technical Publications

Government

Contract Services

(GCS)

- Quality Systems

- Engineering Systems

- Organization and Resource Management

ProductCenter PLM has been proven to provide world-class manufacturers the critical PLM features and capabilities needed to bring greater efficiency to product development efforts. ProductCenter connects your people, information, and processes thereby enabling innovative new products and improved profitability. It improves product definition management and lifecycle automation from concept through to retirement through these six key PLM components.

- Document Management

- Design Integration

- Configuration Management

- Process Management

- Product Collaboration

- Enterprise Integration

ENERGY

Our presence within the Energy industry makes us uniquely qualified to provide the best value for technical services and purchased engineering.

GOVERNMENT / MILITARY

Essig provides comprehensive engineering support for the US Government and Military contracts at extremely low …

AVIATION / AEROSPACE

Essig provides part design, Heat Transfer Analysis, Stress Analysis, Tool & Fixture design, project management …

LOCOMOTIVE

Essig has supported numerous global organizations with engineering resources since 1993. Our team is seasoned and available to take on any technical task.

COMMERCIAL

Essig provides Product Support Engineering service by processing Departure Records, Publication Change Requests, production of technical material, publications and …

TECHNOLOGY

Essig’s worldwide offices provide a global network of skilled professionals, allowing our experienced staff to apply their industry expertise to locate the best-in-class talent …

Date: March 29, 2023 – News

Essig, a leading provider of high-tech engineering, manufacturing and PLM services and solutions, announced that it is celebrating thirty years in business. Established in 1993, Essig’s roots were in engineering design and analysis with the development of complex 3D finite element models and providing thermal and structural analysis of turbine airfoils.

Today, Essig’s companies include Essig Research, Essig MFG and Essig PLM. Essig Research, headquartered in Cincinnati, Ohio, provides a variety of technical services specialized in areas that include R&D, product definition engineering (PDE), test facility engineering (TFE), new product introduction (NPI), maintenance repair and overhaul (MRO) and advanced manufacturing techniques to customers worldwide… Read More.

Date: July 7, 2020 – News

Essig, a leading provider of high-tech engineering, manufacturing and product lifecycle management (PLM) services and solutions, announced that it has acquired Performance Tool LLC, headquartered in Moberly, Missouri. Performance Tool is a best-in-class manufacturer of tools, dies, fixtures, and assorted industrial hardware.

As part of the acquisition, Essig Manufacturing LLC (Essig MFG) was established. Essig MFG adds manufacturing capabilities to Essig’s offerings, allowing it to provide “design-build” services, from initial design to production. This product lifecycle capability has long been sought after by Essig’s large industrial customers. Furthermore, connecting design with build will enable Essig to improve time of delivery, quality and cost of the end product…. Read More.

Date: January 2018 – News

Essig’s latest office opening is a valuable addition to our growing global presence. The Moberly, Missouri office provides Essig with access to talented resources that we can leverage across our customer contracts.

Date: October 2017 – News

Essig is excited to announce the opening of our Indianapolis, Indiana office. This office location is strategically located to provide local support personnel and services to our existing clients and support our continued business development efforts in the region.

Date: Jul 1, 2017 – News

Joe Daly, owner of Essig Research stated “With the expanding network of our global customers we felt the time was right to bring our Essig PLM operations online in Barcelona Spain. We are excited to offer local services and support to our existing European based customers and expand our client base. Our European operations will also provide us with access to skilled development resources to augment our existing US, Puerto Rico, Mexico and Philippines teams.”

Date: October 7, 2016 – News

Joe Daly, owner of Essig Research with operations in the US, Puerto Rico, Mexico and the Philippines. “I recognized a lot of synergy between the Engineering Services work that Essig performs and the Engineering Centric PLM solution ProductCenter. It makes sense to bring SofTech Group Inc. into the family of Essig companies as it helps to round out the value added solutions that we provide to our clients.”

Date: August 4, 2016 – News

A Massachusetts based advanced energy technology company is leveraging Essig Research’s local personnel for SolidWorks design services, ProductCenter PLM software solution and PLM administration services. Joe Daly stated “This is a great example of the design through engineering services that Essig Research is now capable of after acquiring the PLM Business. Essig personnel are assisting in the product design process as well as providing administration and support for the ProductCenter PLM solution which has been deployed. This client engagement showcases our expanding capabilities and we hope to replicate this solution approach for other clients as well.”

Date: September 4, 2015 – News

Essig Research has entered into a longterm relationship with leading aerospace company based in Burlington, NC to supply industry experts as Process Approvers as well as provide guidance in a production environment. Essig has a great reputation for providing aerospace experience and this is another example of the industry recognizing and utilizing that talent.

Date: July 7, 2020 – News

Essig Acquires Performance Tool and Forms Essig MFG

Essig, a leading provider of high-tech engineering, manufacturing and product lifecycle management (PLM) services and solutions, announced that it has acquired Performance Tool LLC, headquartered in Moberly, Missouri. Performance Tool is a best-in-class manufacturer of tools, dies, fixtures, and assorted industrial hardware. As part of the acquisition, Essig Manufacturing LLC (Essig MFG) was established. Essig MFG adds manufacturing capabilities to Essig’s offerings, allowing it to provide “design-build” services, from initial design to production…. Read More.

Date: February 5, 2018 – News

MAEDC Announces Essig Research Expansion into Moberly

The Moberly Area Economic Development Corporation announces the expansion of Essig Research Inc., a Cincinnati, Ohio headquartered company, into Moberly. The company began their Moberly operation in January of 2018 at 1961 Hirst Drive, Ste J., with the hiring of Mechanical Engineers with degrees from Missouri Universities. Joseph P Daly is the founder and CEO of Essig Research. The company specializes in contract design and drafting for aerospace manufacturers…. Read More.

Date: January 2018 – News

Essig opens in Moberly, Missouri

Essig’s latest office opening is a valuable addition to our growing global presence. The Moberly, Missouri office provides Essig with access to talented resources that we can leverage across our customer contracts.

Date: October 2017 – News

Essig opens in Indianapolis, Indiana

Essig is excited to announce the opening of our Indianapolis, Indiana office. This office location is strategically located to provide local support personnel and services to our existing clients and support our continued business development efforts in the region.

Date: Jul 1, 2017 – News

Essig PLM opens in Barcelona Spain

Joe Daly, owner of Essig Research stated “With the expanding network of our global customers we felt the time was right to bring our Essig PLM operations online in Barcelona Spain. We are excited to offer local services and support to our existing European based customers and expand our client base. Our European operations will also provide us with access to skilled development resources to augment our existing US, Puerto Rico, Mexico and Philippines teams.”

Date: Oct 7, 2016 – News

Essig Research owner Joe Daly acquires PLM Business Solutions and Services from SofTech, Inc

Joe Daly, owner of Essig Research with operations in the US, Puerto Rico, Mexico and the Philippines. “I recognized a lot of synergy between the Engineering Services work that Essig performs and the Engineering Centric PLM solution ProductCenter. It makes sense to bring SofTech Group Inc. into the family of Essig companies as it helps to round out the value added solutions that we provide to our clients.”

Date: August 4, 2016 – News

Essig Research to deliver Design Services and PLM to a well-known Cambridge, Massachusetts based advanced energy technology company.

A Massachusetts based advanced energy technology company is leveraging Essig Research’s local personnel for SolidWorks design services, ProductCenter PLM software solution and PLM administration services. Joe Daly stated “This is a great example of the design through engineering services that Essig Research is now capable of after acquiring the PLM Business. Essig personnel are assisting in the product design process as well as providing administration and support for the ProductCenter PLM solution which has been deployed. This client engagement showcases our expanding capabilities and we hope to replicate this solution approach for other clients as well.”

Date: September 4, 2015 – News

Essig Research signs contract with leading aerospace company to provide Aerospace Industry Process Approver Engineering expertise

Essig Research has entered into a longterm relationship with leading aerospace company based in Burlington, NC to supply industry experts as Process Approvers as well as provide guidance in a production environment. Essig has a great reputation for providing aerospace experience and this is another example of the industry recognizing and utilizing that talent.

Date: August 4, 2015 – News

Essig Research signs contract with GE Aviation for Engineering Services in Queretaro, MX

EssigQ has opened in Queretaro, MX to best support GE Aviation (GEIQ) locally in the fast growing Queretaro area. EssigQ will be providing high quality Engineering Services at a competitive cost to our clients at this strategically located facility.

Innovative Approaches Delivering Significant ROI

Essig recently successfully designed a repair tool for a top aircraft engine supplier to enable an in-field compressor spool machining operation without full engine teardown.

Essig was assigned to actually perform the machining operation and travelled to approximately 20 US Naval bases worldwide performing the operation on ~40 US Navy ship units. Cost savings due to not having to disassemble, ship, repair and replace was estimated at $4.9m per engine.

Experience Expedites Results

A technologically advanced aircraft engine company continues to utilize the Essig team in a Process Approval role for their tooling, repair and maintenance procedures.

They are leaning on Essig’s senior experience with aerospace industry expertise to write workflow, shop manuals and procedures.

Government Clearance Allows for Effective Collaboration

A long established customer has been leveraging Essig team members on next generation military engine design.

We have also provided high level support for their helicopter engine design as well as cost and weight reduction projects for in service engines.

Creative Partnering Results in Customer Satisfaction

Entered into an innovative new program with Essig, allowing us to engineer, design and develop a part repair, while also taking on inspection of the repaired parts.

The program is not Time & Material for the engineering and design, but rather a part sales revenue split once the part is accepted and released to customers for use.

Essig’s customer, a turn-key energy storage systems company, has engaged us to engineer, design, develop a part is not responsible for payment until the part is sold, and Essig wins with a larger revenue due to taking on labor costs up front.

Enabling Companies to be More Effective

A global commercial aircraft engine supplier relies on the Essig Design team to innovate utilizing cutting edge technologies such as CMC (Ceramic Matrix Composites), Additive Manufacturing techniques and Model Based Definition for their 3D CAD models.

Essig designers also utilize CAD2CAM initiatives to considerably reduce CAM programming and hardware checking time.

Innovative Approaches Delivering Significant ROI

Essig recently successfully designed a repair tool for a top aircraft engine supplier to enable an in-field compressor spool machining operation without full engine teardown.

Essig was assigned to actually perform the machining operation and travelled to approximately 20 US Naval bases worldwide performing the operation on ~40 US Navy ship units. Cost savings due to not having to disassemble, ship, repair and replace was estimated at $4.9m per engine.

Experience Expedites Results

A technologically advanced aircraft engine company continues to utilize the Essig team in a Process Approval role for their tooling, repair and maintenance procedures.

They are leaning on Essig’s senior experience with aerospace industry expertise to write workflow, shop manuals and procedures.

Government Clearance Allows for Effective Collaboration

A long established customer has been leveraging Essig team members on next generation military engine design.

We have also provided high level support for their helicopter engine design as well as cost and weight reduction projects for in service engines.

Creative Partnering Results in Customer Satisfaction

Entered into an innovative new program with Essig, allowing us to engineer, design and develop a part repair, while also taking on inspection of the repaired parts.

The program is not Time & Material for the engineering and design, but rather a part sales revenue split once the part is accepted and released to customers for use.

Essig’s customer, a turn-key energy storage systems company, has engaged us to engineer, design, develop a part is not responsible for payment until the part is sold, and Essig wins with a larger revenue due to taking on labor costs up front.

Enabling Companies to be More Effective

A global commercial aircraft engine supplier relies on the Essig Design team to innovate utilizing cutting edge technologies such as CMC (Ceramic Matrix Composites), Additive Manufacturing techniques and Model Based Definition for their 3D CAD models.

Essig designers also utilize CAD2CAM initiatives to considerably reduce CAM programming and hardware checking time.